Luoyang Spindle Technologies Co,.LTD. is a scientific and technological spindle in the high-speed motor production enterprises.The company has a high technology experts, technicians and other talents composed of high-speed motor and spindle development team, with all kinds of high-speed rotating equipment development capabilities.

Luoyang SUF Spindle Technologies Co,LTD is a scientific and technological spindle and medium and high speed motor manufacturer. The company has high technology experts, technicians and other talents in the development of high-speed motors and spindles, with all kinds of high-speed rotary equipment development capabilities.

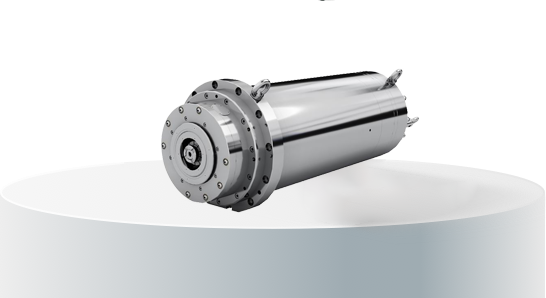

Our company focuses on technology research and development to meet individual needs as a feature, mainly engaged in the design and development of special machine tool spindles, special industry with the design and manufacture of drive motors business. The spindle motors developed range from 2 to 120,000r/min in speed and 0.5 to 250kW in power. The types of motors include asynchronous motors, permanent magnet synchronous motors and DC brushless motors.

Our company mainly produces machine tool spindles, the main product categories are grinding spindles, lathe spindles, heat pipe high-speed rotary spindles, carving (milling) spindles, high-speed centrifuge spindles, precision machinery spindles (belt-driven, motor-direct-driven), and so on, but also in accordance with the user's needs to customize the special spindles, to provide the spindle from the design of the product to the accessory supporting, installation and commissioning of the spindle to use the whole life cycle of the full range of services, but also to undertake the maintenance of various types of domestic and foreign spindles.

The company's major R&D projects since 2016::

Using the special preload structure of bearings, a new type of high-speed deep hole drilling (gun drilling) electric spindle was developed, which solved the problem that the electric spindle could not withstand the high hydraulic axial force.

Developed a 12,000r/min, 24kW tool grinding spindle using the HSK A63 automatic tool changer system, the main performance of which reaches the level of the German Reckerth spindle.

Adopting new sealing structure and cooling structure of spindle bearing and motor, we have developed 100,000-rpm ultra-high-speed internally cooled grinding electrospindles, realized water spraying and cooling of the shaft of high-speed electrospindles, solved the cooling and lubrication problems of small blind hole grinding, and improved the grinding efficiency from 15s/pcs to 7s/pcs.